o ring channel design|Parker Engineering Your Success Motion Control Technology : Baguio The design tables displayed above were created using best practices, including Compression Ratio, O-Ring Extrusion, Concentricity and Diametric Gap, and Backup . Tingnan ang higit pa standard note 3) prohibited zone non- potable fluid prohibited zone new water perpendicular crossing city of ontario water main separation standards engineer ap roved py: louis abi-youn rfpmmende professio no. 44485 exp. 03/31/18 44485 rce date 6226b rce date by date standard drawing number 4001 rev description

PH0 · The Ultimate Guide to O

PH1 · Parker O

PH2 · Parker Engineering Your Success Motion Control Technology

PH3 · O

PH4 · How to: design an o

PH5 · Groove Design: O

Arras A traditional staple of a Filipino wedding symbolizing future prosperity for the bride and groom, these wedding unity coins are a lso known as "arras". It is usually presented at the wedding church ceremony and blessed by the priest or officiant.Get your own arras and other wedding accessories here.Rizal Province ZIP Codes, Postal Codes, and Phone Area Codes. Rizal Province is recognized as the “Cradle of Philippine Art” because of its artistic communities and folk festivals. It is located in Calabarzon, and its capital is Antipolo.

o ring channel design*******Global O-Ring and Seal has developed o-ring groove design and gland dimension guidelines. These are intended for use in basic design consideration and to understand the core principles involved in o-ring gland/groove design. Numerous factors go into the appropriate design of a . Tingnan ang higit pa

The o-ring cross-section in your design will determine all your subsequent dimensions and specifications. Standard o-rings are available in various cross-sections and inside . Tingnan ang higit pa

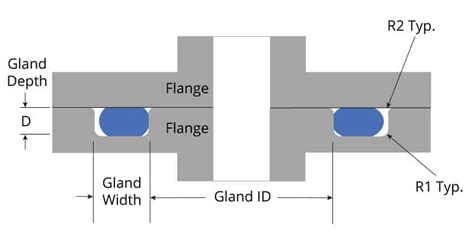

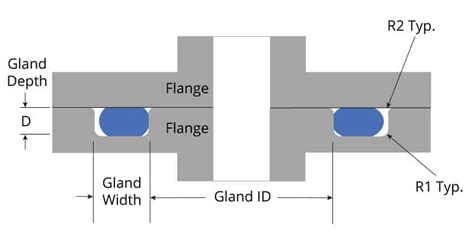

Below, four standard application groove design guidance tables are presented along with dimensional reference drawings. The first table is for industrial face or . Tingnan ang higit pa

The design tables displayed above were created using best practices, including Compression Ratio, O-Ring Extrusion, Concentricity and Diametric Gap, and Backup . Tingnan ang higit paO-ring groove design guides offer default dimensional guidance on the most basic o-ring groove design applications. The best o-rings are useless without the right groove design .

The o-ring groove (O-ring gland) is the most important design feature for producing efficient O-rings. They come in different shapes and sizes depending upon the .

Designing the parts of an application where o-rings will be applied is broadly termed “o-ring groove design”. In order to seal properly, the o .

O-ring groove design is a key consideration in the o-ring selection process. Browse design considerations and recommendations for static face seals, metric o-rings, static dovetail .

O-rings are reliable and affordable, which is why they’re a popular solution. But you need a good groove design for the O-ring to do its job properly. This guide will walk you through our best tips for designing O .

Parker Engineering Your Success Motion Control Technologyo ring channel design Parker Engineering Your Success Motion Control TechnologyHow to: design an o-ring groove - Vizeng. By Paul Vizzio. O-rings are generally the most reliable and repeatable way to achieve water and air-tight sealing in assemblies for both static (stationary) and dynamic .

Groove O-Ring Design: Seals for Static and Non-Rotary Dynamic Applications. Speak to an Engineer About Your Project. Cross-section. Select an O-Ring cross-section size from the available standard sizes. . Table of Contents. The Basics of O-Rings. In this section, we will cover the fundamental aspects of O-rings, including their construction, materials, and the different .

Parker Engineering Your Success Motion Control TechnologyThis design technique minimizes movement of the O-ring in the groove due to pressure, thereby virtually eliminating wear and pumping leakage. If this principle is used, groove diameters larger or smaller than .

O-Ring Design Guides for Engineers. O-ring design guides for engineers help select the best o-ring material specifications for your applications. O-ring design guides include o-ring sizing charts, o-ring groove design references, o-ring chemical compatibility guides, o-ring tolerances and failure analysis guides, and o-ring material selection .

Our o-ring groove design guides list default o-ring groove dimensions for the most basic applications and are intended to be used with the following o-ring groove design considerations to engineer on o-ring gland to optimize specific application performance. The wrong size groove makes even the best o-ring underperform.

0.002. 1. Learn more about static o-ring groove design for rod, cylinder, and piston o-rings from Marco Rubber, the industry leader in standard and custom o-rings.

o ring channel design0.002. 1. Learn more about static o-ring groove design for rod, cylinder, and piston o-rings from Marco Rubber, the industry leader in standard and custom o-rings.

Need an O-ring for your application? Use our interactive O-ring calculator to help select the optimum size O-ring to use, in accordance with the principles within ISO 3601. . Our seal products range from simple static O-rings to complex and bespoke seal designs in specialist materials. Whatever your application, we have the seal product for .A higher durometer or an abrasion resistant material is recommended for these applications. User our o-ring groove design guide for basic recommendations and technical definitions to help you identify your exact o-ring groove design. Then easily order your desired o-ring groove design online from the world’s largest o-ring inventory. The Parker O-Ring Handbook is a hardcover manual with 11 chapters detailing O-ring design. The chapters range from tutorial to purely technical in nature. For instance, technical chapters provide .Note 1: Groove Depth = machined channel Gland Depth = Groove Depth + Clearance. Note 2: The following sizes are not normally recommended for dynamic service, although special applications may permit their use: Note 3: Clearance shown are based on 70 durometer materials. The clearances must be held to an absolute minimum consistent .Parker Engineering Your Success Motion Control Technologyring could easily track the required delta gap of 0.018 inch at the gap opening rate of 0.19 inch/sec. tion tests conducted at 75'F and120°F, the O-ring maintained contact throughout the. delta gap opening of 0.018 inch. The External Tank/SRB a. tach strut load vibrations had anegligible effect on the ability of the.This O-ring seal design section will give you step by step instructions on how to design a seal or rubber part for your application. Consider this a rubber guide or O-ring guide in helping you find the exact rubber material and size you need. Some parts of this online rubber or O-ring design guide can be downloaded in PDF but everything can .METRIC DOVETAIL GROOVE DESIGNS. The Surface Finish X, groove top and bottom: For liquids X= 32 micro inches. For vacuum and gases X=16 micro inches. For groove sides X=63 micro inches. Radius “R” is .

An O-ring has proved to be a practical rotary shaft seal in many applications. With the correct design, Parker O-Ring rotary seal compound N1090-85, will provide satisfactory service at surface .

Metric o-ring groove dimensions are listed for the most common metric cross sections with and without backup rings. Contact Us for samples. Skip to content. . O-Ring Groove design plays an important part in how an o-ring seals. Learn More > Contact. Call Us: 716-759-2222; Send us a message; Call Us. 716-759-2222. Employment; Home; Products.

The online O-Ring Calculator offers engineers and professionals a quick and easy way to calculate O-Ring dimensions and the appropriate housing layout in accordance with the international O-Ring standard ISO 3601. By simply entering installation specifications for an application, it recommends O-Ring sizes, housing layout and corresponding part .The first O-ring groove dimension we will cover is the O-ring groove width. The horizontal span of the groove should be sufficient to allow for full expansion of the O-ring within the groove. The horizontal span should only allow for a 5% expansion of the O-ring diameter. The OD (outside diameter) of the gland should be larger than the ID .Static O-Ring Sealing Parker Hannifi n Corporation • O-Ring Division 2360 Palumbo Drive, Lexington, KY 40509 Phone: (859) 269-2351 † Fax: (859) 335-5128 www.parkerorings.com Parker O-Ring Handbook 66° Mean Groove Diameter Coincides With Mean O-ring Diameter. Finishes are RMS values L G R R 1 O-Ring Dovetail .AS568B STANDARD O-RING GROOVE DESIGN. Contact Us For Assistance Or Samples Click Here and contact us today to receive a quote or if you have any questions regarding sizing. The three main types of standard groove designs are Industrial Static also called Radial, Industrial Reciprocating also called Dynamic, and Face Seals also called Axial or .

Special terms for Blackjack online games. In casino play you will often notice special terms explaining different options of this dealer game. Playing Blackjack the dealer will give himself two cards one face up and one card face down. That means the hand of the dealer will be shown only partially with one card.

o ring channel design|Parker Engineering Your Success Motion Control Technology